Clamp-on Type Flow Sensor PFUW

Application Examples

Applicable Fluids:

General Liquids, Beverage, Oil, Antifreeze, Chemical liquids, Water, High-pressure fluid

FAQ

Click here for more details of flow switches.

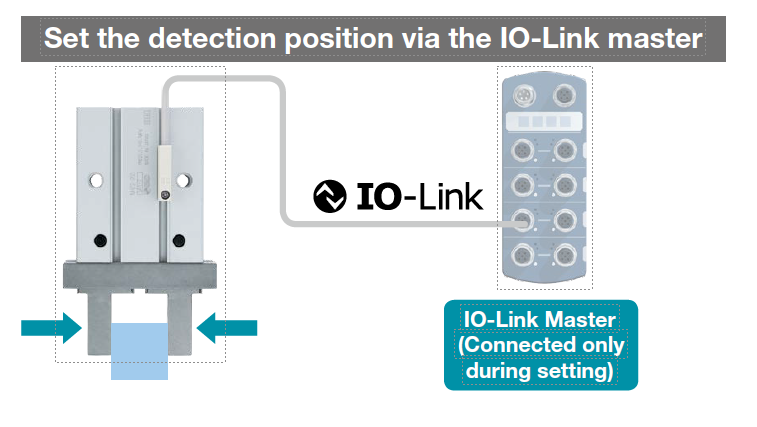

IO-Link Compatible 2 in 1 Auto Switch D-MH2*

Detection position setting can be done away from the actuator

FAQ

Click here for more details of auto-switches.

Click here for more FAQ of products.

New Product Launching

|

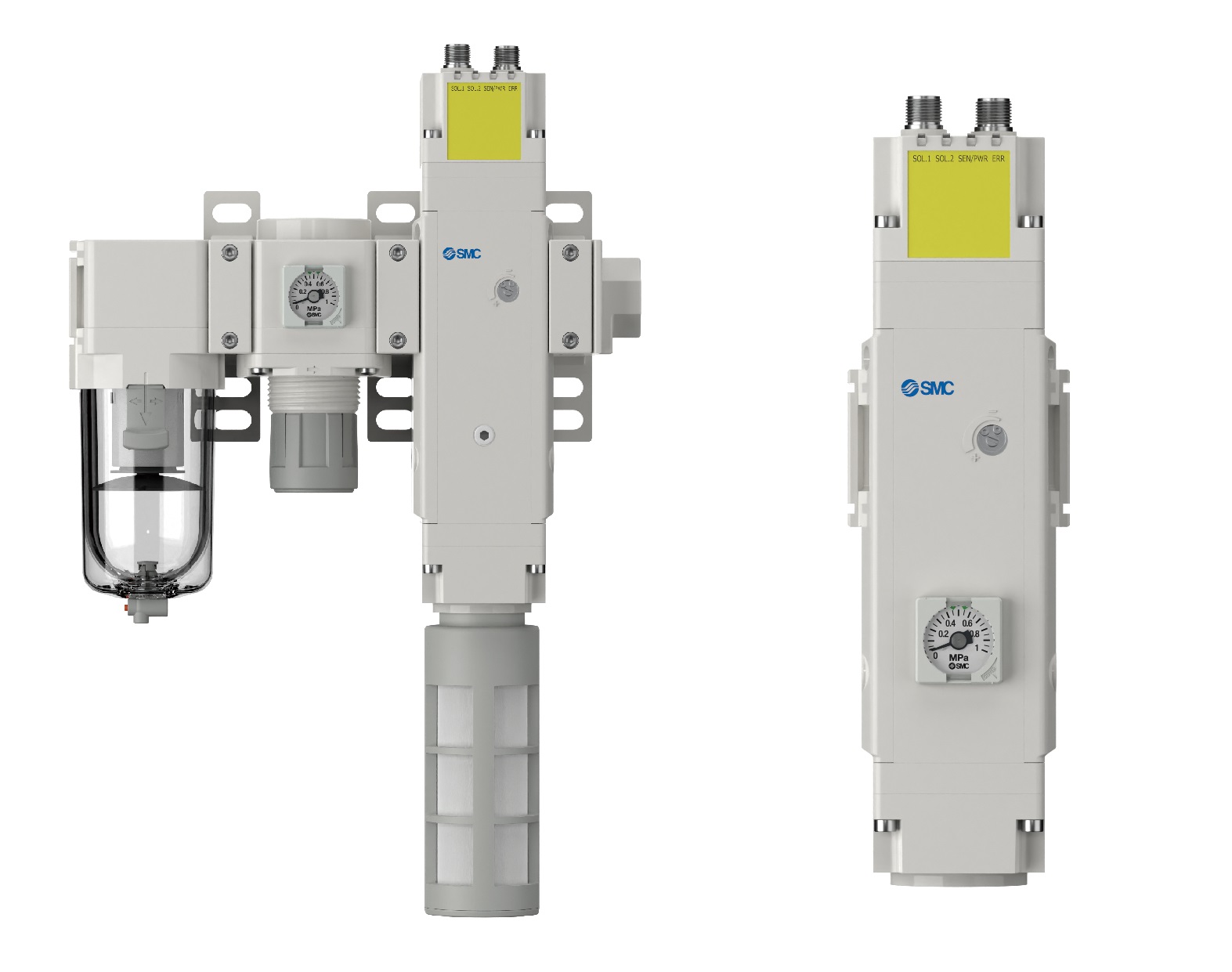

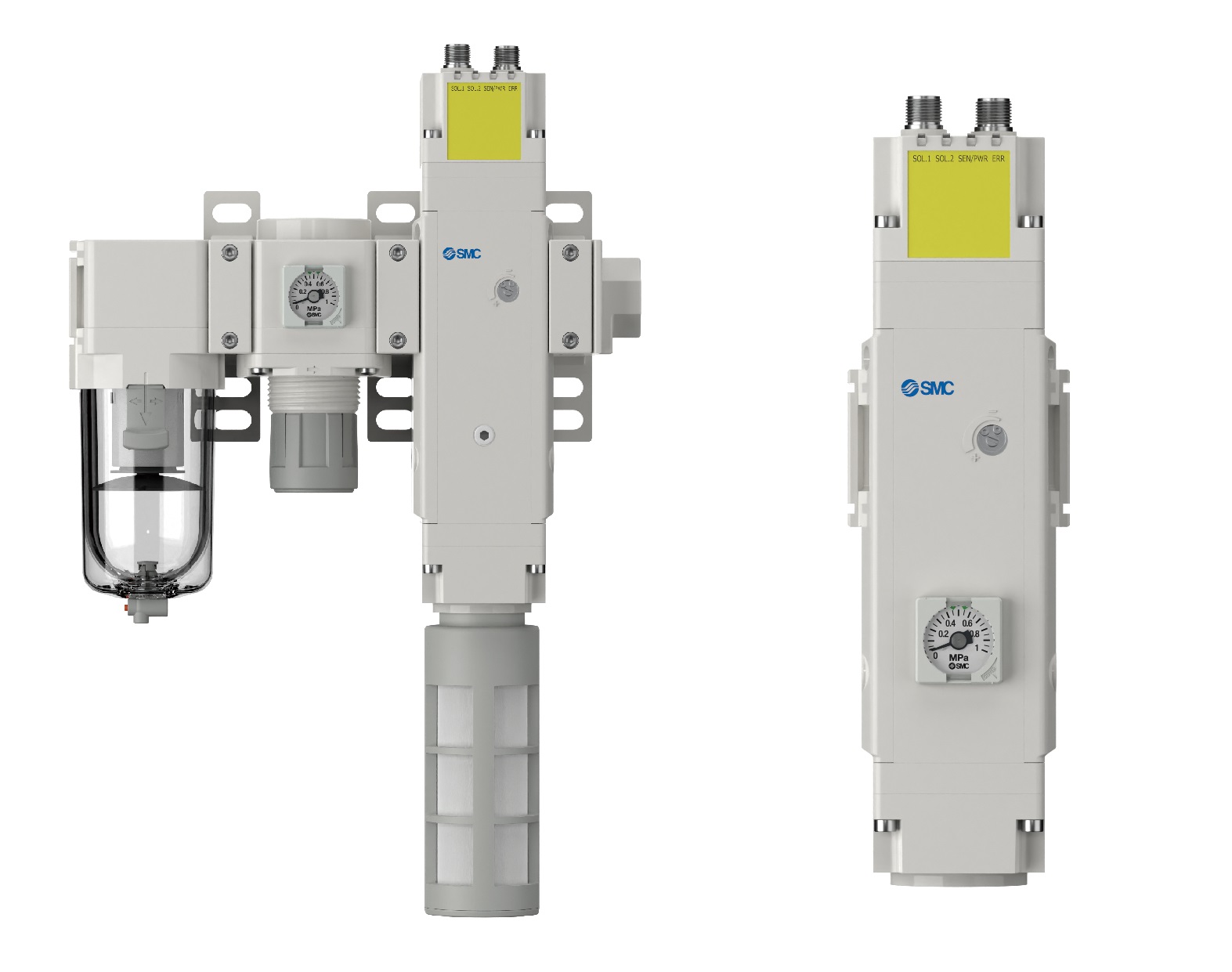

Safe Exhaust Valve : VPX400 Series

ISO 13849-1 Compliant | Modular Connection Type

|

Key Benefits:

- Safety Assured: Fully compliant with ISO 13849-1 safety standards, meeting rigorous Category 3 and 4 requirements.

- High Performance: Outstanding exhaust flow rates at 0.6 MPa:

- 10,500 L/min (VPX406-A3)

- 13,000 L/min (VPX406-A3)

- 15,000 L/min (VPX406-A6)

- Compact & Lightweight: Combines three essential safety functions in one streamlined design:

- Dual residual pressure release valve

- Soft start-up valve

- Main valve inconsistency detection

- Flexible Integration: Modular connection capability supports compatibility with AC30/40/50/60-D series.

View PDF |

|

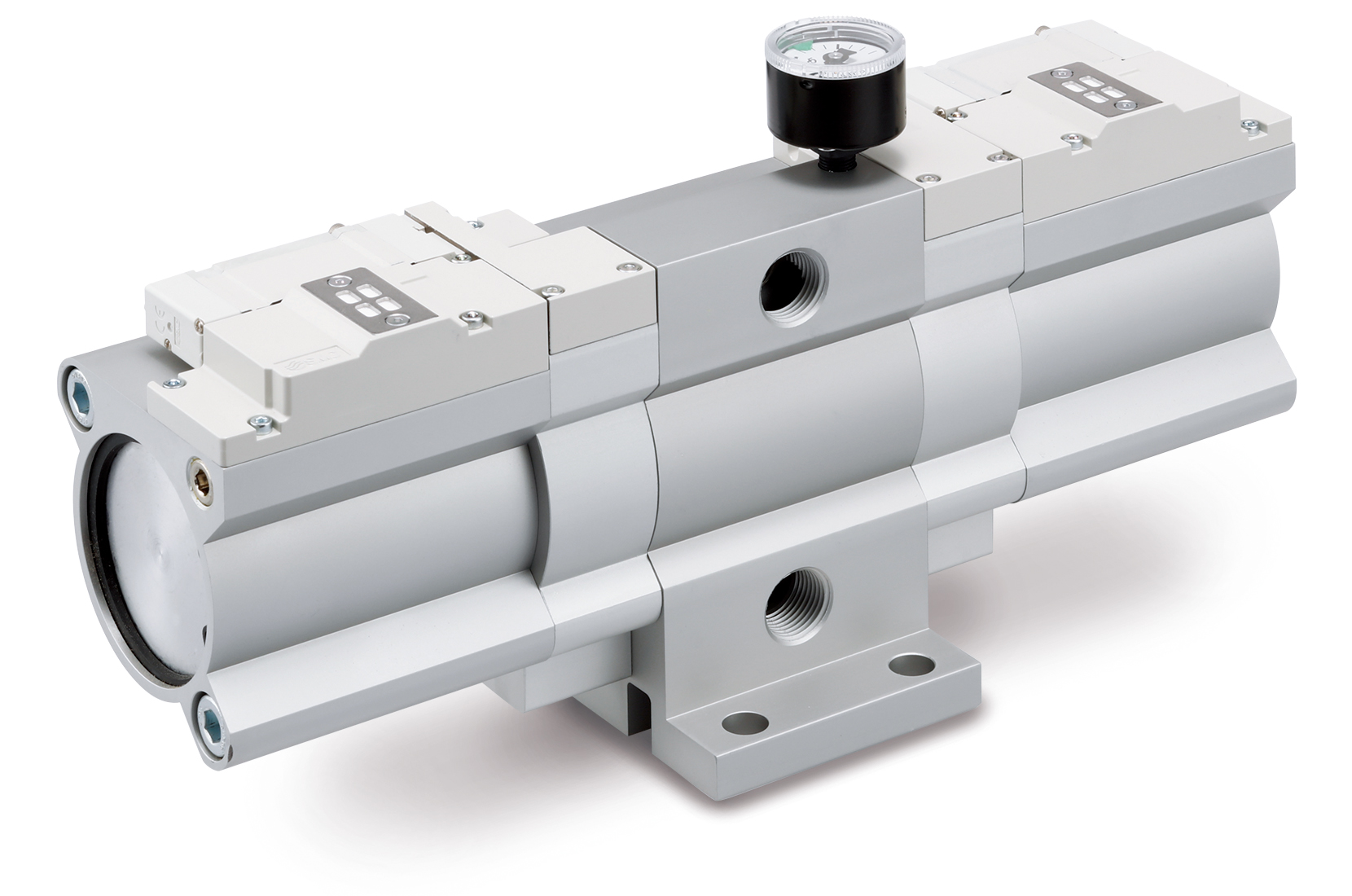

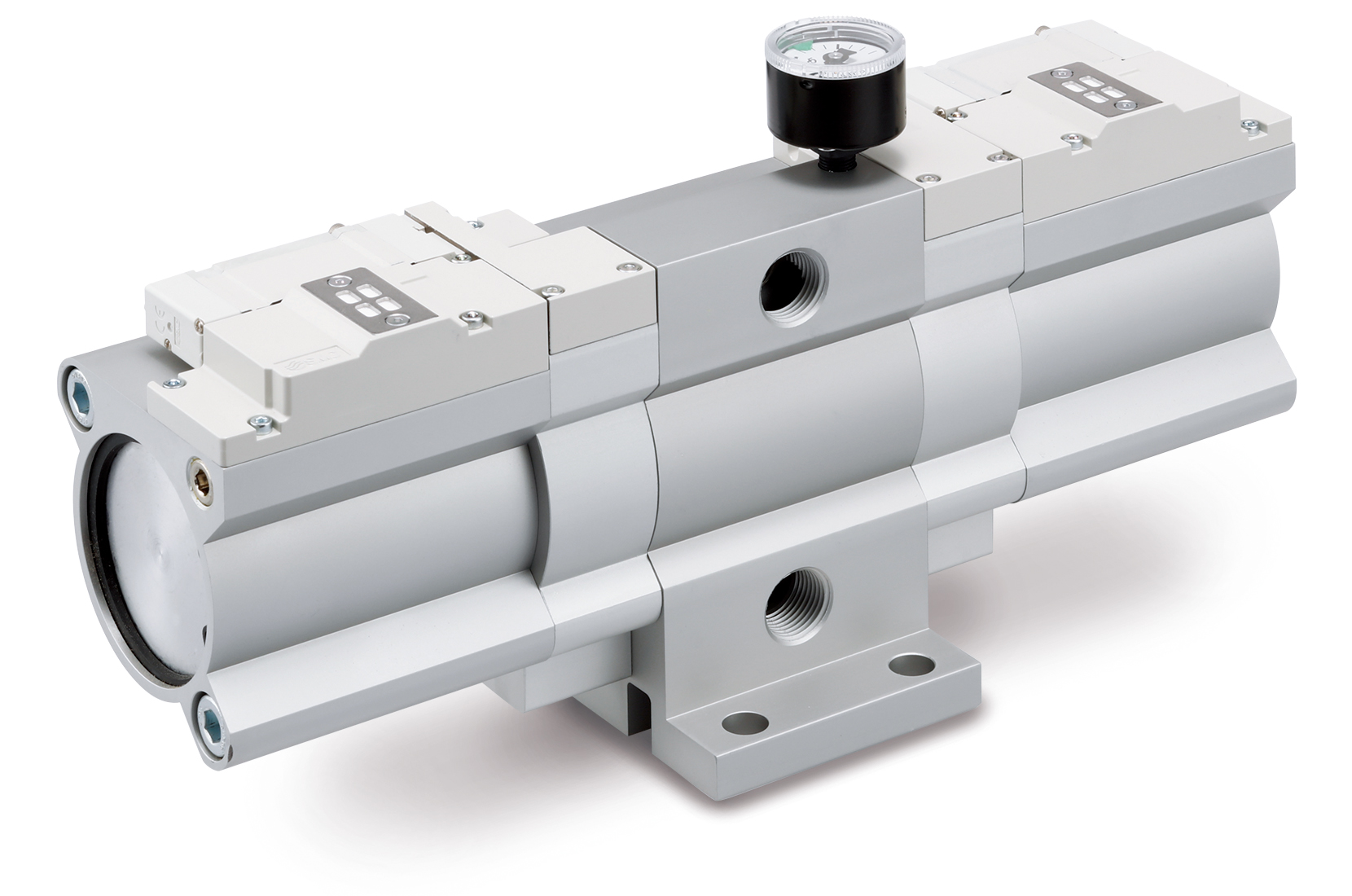

Energy-Saving, Exhaust-Recovery Booster Regulator: VBAE Series

|

- Significant Energy Savings:

- Achieves up to 40% reduction in CO2 emissions and air consumption, supporting eco-friendly operations.

- Operates by reusing exhaust air, reducing overall energy waste.

- Enhanced Air Pressure:

- Boosts factory air pressure by 1.7 times using air-only operation, eliminating the need for an external power supply.

- Low-Noise Operation:

- Delivers a quiet work environment with an operation noise of 65 dB (A)—a 15 dB (A) reduction compared to the previous VBA series.

- Fast and Efficient Performance:

- Shortens charging time by up to 50%, increasing productivity.

- Extended Service Life:

- Improved durability reduces maintenance frequency, ensuring longer, uninterrupted operation.

- Flexible Installation Options:

- Compatible with both vertical and horizontal installation configurations for versatile use.

- Mounting interchangeability with the existing VBA series simplifies upgrades and replacements.

- Easy Installation:

- Air-only operation removes the need for electrical wiring, simplifying installation and reducing setup costs.

View PDF |